I wanted to make a belt for a friend, as part of a new set of 13th century English clothing. I have made many belts before, but this one was also a chance to try my hand at a new craft – pewter casting!

Design

I looked at 13th century English manuscript illuminations to get an idea of style, width, length and decoration – the belts appeared quite narrow, to mid thigh, commonly black, with abundant silver or gold coloured mounts. Strap ends (belt chapes) were not common at this time.

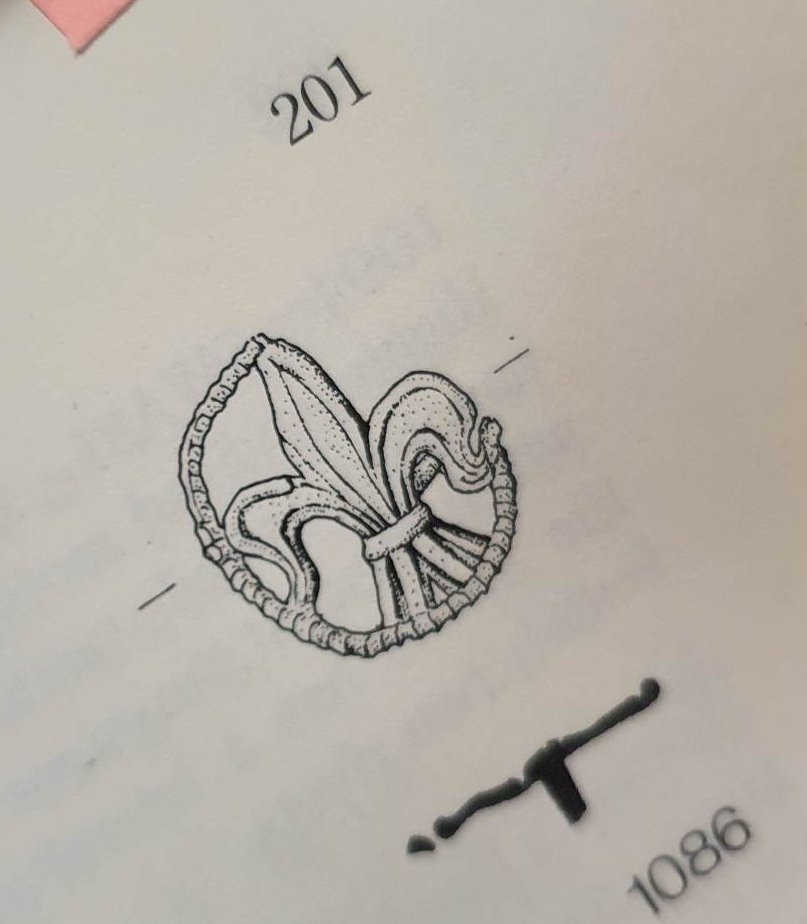

Next, I looked for details of the shape and size of 13th century English belt buckles and mounts. Dress Accessories (Egan & Pritchard 1991) had several examples of both. The lobed oval buckle style was common from the late 12th to early 14th century, many with buckle plates. Most finds were made of copper alloy. I had a suitable buckle in brass, and could make a buckle plate to match from sheet brass.

Next step was to source 20 brass mounts of a suitable style, size – and price! After several fruitless hours searching online suppliers, I put the project aside in frustration.

Some months later, I had the chance to play with pewter casting, and needed a project – the belt was ideal! I had the same style buckle in pewter (minus the pin), and some thin pewter-look aluminium sheet for the buckle plate, and I could try my hand at casting the rivets and mounts.

I liked the appearance of the 13thc fleur-de-lys mount with the filigree edge, and thought I could adapt the design to show a pheon (arrowhead), to reflect the recipient’s love of archery. Little did I realise how much harder filigree designs were to cast…

Source: Dress Accessories (Egan & Pritchard 1991)

After several attempts, I finally got my mould working well and cast 20 mounts. The original mount has a single integral rivet, but I made mine with two, as per other contemporary examples.

I made the buckle pin from fencing wire, and the buckle plate from the sheet aluminium (drill press, hacksaw, file). I made another 3-part soapstone mould and cast some rivets to secure the buckle plate.

I cut the leather strap, slicked the edge smooth, dyed it black, polished it and worked the belt to soften it. Then I punched holes and attached the buckle and plate using the pewter rivets, peened flush at the back. The mounts were likewise attached by trimming the integral rivets and peening over – no need for roves (extant finds with roves/washers are uncommon).

Afterthoughts

I’m quite pleased with the belt – and very pleased I finally got to play with pewter casting! The rivet heads are bit heavy, and I’d love to have access to rolled pewter for the buckle plate, but the overall effect is good. Now it needs a matching purse…