This rope bed sleeps two, is surprisingly comfortable and packs down for transport.

The bed was built to replace an early ‘quick and dirty’ version, which we had been using since 2003. It has some clever joinery in the posts and is easy to put up and pack down. Many people (especially if large) prefer a slatted bed, but this works well for us.

Research and Design

Camp beds – that is, demountable beds for travelling – were known from at least the 15th century. Military officers had pack-down beds inn their camps, which were then adopted by nobles who wanted to be sure of a comfortable bed on their travels between estates.

The Medici inventory of 1553 mentions ‘a couch of walnut for the field, to take apart in several pieces’ together with its leather valise (Thornton 1991).

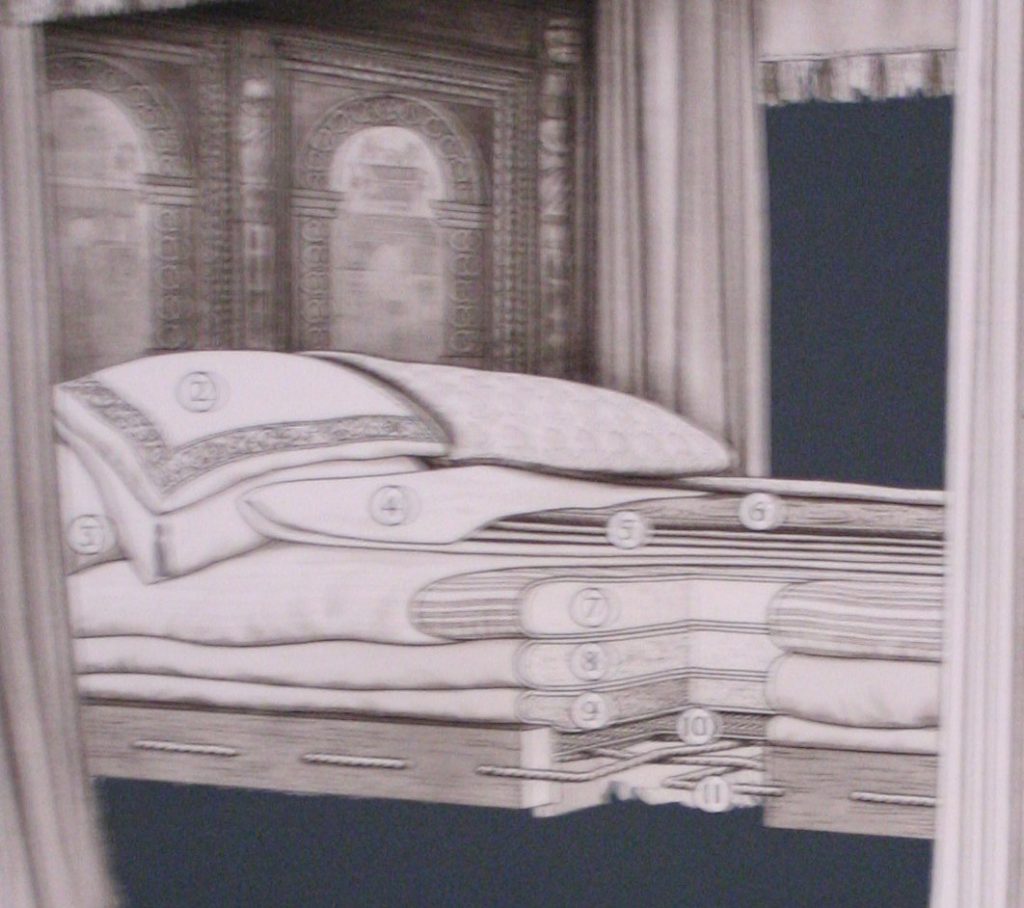

Beds seen in tents are usually covered in bedding, so it is difficult to tell how they were actually constructed. Extant bed frames from the 16th century show holes around the frame to string the typical rope mattress. In 2008, I was thrilled to find an exhibition on renaissance beds at the Victoria & Albert Museum and took some (slightly fuzzy) photos.

Source: Period Oak Antiques

Photo: Robyn Spencer

Photo: Robyn Spencer

The V&A detailed the many layers in a 16th century high status bed:

- Bed cords – hemp rope

- Bed mat – Plaited rush, sewn with hemp twine

- Three mattresses – unbleached canvas filled with flocks (unspun wool), canvas stuffed with feathers, and striped linen stuffed with down

- Middle mattress – unbleached canvas stuffed with feathers

- Upper mattress – striped linen canvas with down

- Sheets – fine linen

- Quilt – stuffed with flocks

- Blanket – Twill woven wool

- Bolster and pillows – Striped linen canvas with feathers, fine linen cover

- Coverlet – Wool/linen brocade

A camp-bed would have less layers, but it’s a great basis to work back from.

Construction

The bed was sized to be a standard double bed. We have a queen sized bed at home, but the smaller bed fits better into the tent and takes less storage room.

My husband Nico constructed the bed frame using power tools. The 4 rails are made of 90 x 45mm pine with stepped dovetail joints on the end – facing up on the short rails, and down on the long ones. Holes are drilled along the rails every 125mm, countersunk to reduce wear on the ropes.

The posts were made of 90mm square timber, with the ends turned on the lathe, and topped with a commercial pine finial. Each post has a rabbet on the two interior faces to take the rails. Once the rails are in place, they lock into each other within the post.

I added a little gold paint to the post finials, and then oiled the frame well.

Hemp rope would be ideal, but us hard to get, so we used 6mm sisal rope – thinner rope is more comfortable to sleep on! I cut two ropes, each 25m long, and whipped the ends with waxed linen thread.

Assembly

It is much easier to assemble the bed outside the tent. We leave one rope loosely strung on the long rails, to save time when assembling the bed in the field. To make the bed, we unroll the rails, then lay them out. We put the short ends together, then slot in the long rails and tighten the first rope to hold it all together.

Then we weave the second rope through, alternating rows like a tennis racquet. The final step is to tighten the ropes as much as possible – much easier with two people, working from the fixed end of each rope in turn. Once tight, we take the bed into the tent.

Next is the rush matting, laid across the ropes. This makes a huge difference to comfort and spreads the load, reducing the ‘roll to the middle’ problem. We bought a couple of jute mats from Ikea, which roll up easily for storage. Then a thin base mattress and a feather topper, sheets, quilt and blanket.

The ropes do stretch a little in use. We usually have to remove all the bedding and tighten up the ropes after a couple of days.